Abrasive blasting is an essential process in the oil and gas industry, used for surface preparation, rust removal, and cleaning of industrial equipment. The success of this process largely depends on selecting the right blasting media. With various abrasive materials available, choosing the best option requires understanding the specific needs of the application, environmental impact, and cost considerations.

Understanding Abrasive Blasting

Abrasive blasting, often referred to as sandblasting, involves propelling a high-speed stream of abrasive particles against a surface to clean, roughen, or remove contaminants. This process is widely used in oil and gas for maintaining pipelines, storage tanks, offshore structures, and drilling equipment.

Each abrasive medium has unique properties that make it suitable for specific applications. The choice of blasting media should consider factors such as surface material, desired finish, and the level of abrasion required.

Types of Abrasive Blasting Media

- Walnut Shells and Corn Cobs: Environmentally Friendly Options

For delicate surfaces such as fiberglass or soft metals, organic abrasives like walnut shells and corn cobs are ideal. They do not cause etching or damage, making them suitable for removing coatings and light contaminants. Additionally, they are biodegradable and environmentally friendly. - Glass Beads: Achieving a Smooth Finish

Glass beads, made from soda-lime glass, are a great option for applications that require a smooth and polished finish. They provide minimal stress on the substrate, making them useful for cleaning and deburring metal parts. They are also reusable, offering cost efficiency. - Aluminum Oxide: Ideal for Paint and Rust Removal

Aluminum oxide is a sharp and hard abrasive commonly used for removing paint, rust, and corrosion from metal surfaces. It provides a high cutting speed and is available in various grit sizes, making it one of the most versatile blasting media. - Plastic Media: Best for Automotive and Aerospace Components

Plastic media is a soft, non-damaging abrasive ideal for removing coatings from delicate surfaces such as automotive parts and aerospace components. It minimizes dust generation and ensures no structural damage to the substrate. - Silicon Carbide: Fast Etching for Hard Surfaces

Silicon carbide is one of the hardest abrasives available, offering aggressive cutting action for etching glass, stone, and hard metals. It is also effective in removing tough coatings and corrosion. - Steel Shot and Steel Grit: Heavy-Duty Cleaning and Peening

Steel abrasives are widely used in the oil and gas industry for cleaning and strengthening metal surfaces. Steel shot is round and suitable for polishing, while steel grit has an angular structure that provides aggressive cleaning action for rust and scale removal. - Avoiding Sand as a Blasting Medium

While the term “sandblasting” is still commonly used, actual sand is rarely used due to health hazards associated with silica exposure. Inhaling fine silica dust can lead to severe respiratory illnesses, such as silicosis. Additionally, sand retains moisture, which can lead to equipment clogging and reduced efficiency.

Selecting the Right Abrasive for Oil and Gas Applications

Choosing the correct abrasive for oil and gas applications depends on various factors, including:

- Surface Type: Ensure the media is suitable for the material being cleaned or prepared.

- Desired Finish: Some abrasives provide a smooth finish, while others create a rough texture for better adhesion.

- Environmental Considerations: Opt for biodegradable or recyclable abrasives to minimize environmental impact.

- Cost Efficiency: Consider reusability and longevity of the media.

Superabrasives and Grinding Media in Petroleum Engineering

In addition to traditional blasting media, specialized abrasives such as superabrasives are used in the manufacturing and maintenance of drilling equipment.

Diamond Abrasives for Precision Cutting

Polycrystalline diamond (PCD) abrasives are commonly used in the manufacturing of drill bits and wear-resistant components. These abrasives provide superior hardness and durability, making them ideal for cutting and grinding applications in oil drilling operations.

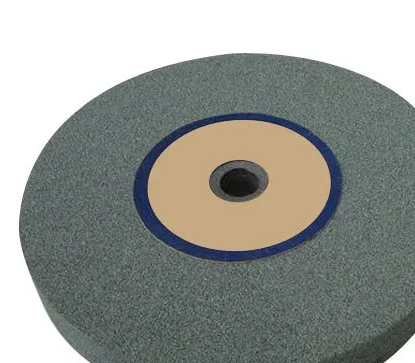

Bonded and Coated Abrasives for Heavy-Duty Grinding

Bonded abrasives, including resinoid and vitrified abrasives, are used for precision and rough grinding of critical components such as couplings, stabilizers, and pump plungers. Coated abrasives, available in belts, discs, and sheets, are used for finishing, polishing, and lapping applications.

Benefits of Using the Right Blasting Media in Oil and Gas

Using the appropriate abrasive blasting media ensures the following benefits:

- Increased Efficiency: Reduces processing time and enhances surface preparation.

- Cost Savings: Longer-lasting abrasives lower operational costs.

- Safety Compliance: Reduces health hazards associated with airborne particles.

- Environmental Protection: Minimizes waste and ecological impact.

Choosing a Reliable Supplier

With numerous blasting media suppliers in the market, selecting a reputable provider is crucial. Consider the following before making a purchase:

- Expertise and Knowledge: Ensure the supplier has technical knowledge and experience in abrasive blasting.

- Product Quality and Compliance: Verify that the media meets industry standards and safety regulations.

- Technical Support and Training: A good supplier should provide guidance on proper usage and maintenance.

- Equipment Compatibility: Ensure the media is compatible with existing blasting equipment.

Final Thoughts

Abrasive blasting plays a critical role in the oil and gas industry, ensuring that equipment and infrastructure remain in optimal condition. Selecting the right blasting media enhances efficiency, improves safety, and reduces costs. Companies operating in Qatar’s oil and gas sector should invest in high-quality, industry-approved abrasives to achieve the best results.

For accessing top-tier abrasive blasting products from the world’s leading manufacturers, please forward a request for quote at www.mroqatar.com today.